- English

- русский

- العربية

- tiếng Việt

- Türkçe

- Deutsch

- 日本語

- 한국어

- ภาษาไทย

- Indonesia

- שפה עברית

- Português

- Español

- Français

- Italiano

- Nederlands

- Polski

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Gaeilge

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Future of Automotive Engine Mounts in 2025 Your Essential Checklist for Global Procurement

As the automotive industry embraces rapid advancements in technology and sustainability, the future of Automotive Engine Mounts is set to transform significantly by 2025. According to a recent market report by Allied Market Research, the global automotive engine mount market is projected to reach USD 5.1 billion by 2025, with a CAGR of 5.2% from 2020. This growth is driven by increased vehicle production, the rising demand for electric vehicles, and the need for enhanced noise, vibration, and harshness (NVH) characteristics. Additionally, the shift towards lightweight materials and innovative designs will redefine procurement strategies and production processes. With China continuing to emerge as a leader in manufacturing excellence, the commitment to quality and innovation in automotive components is crucial for global suppliers. As industry stakeholders prepare for these changes, understanding the evolving market dynamics and leveraging advancements in Automotive Engine Mount technology will be essential for maintaining a competitive edge in the global procurement landscape.

Emerging Technologies Shaping Automotive Engine Mounts by 2025

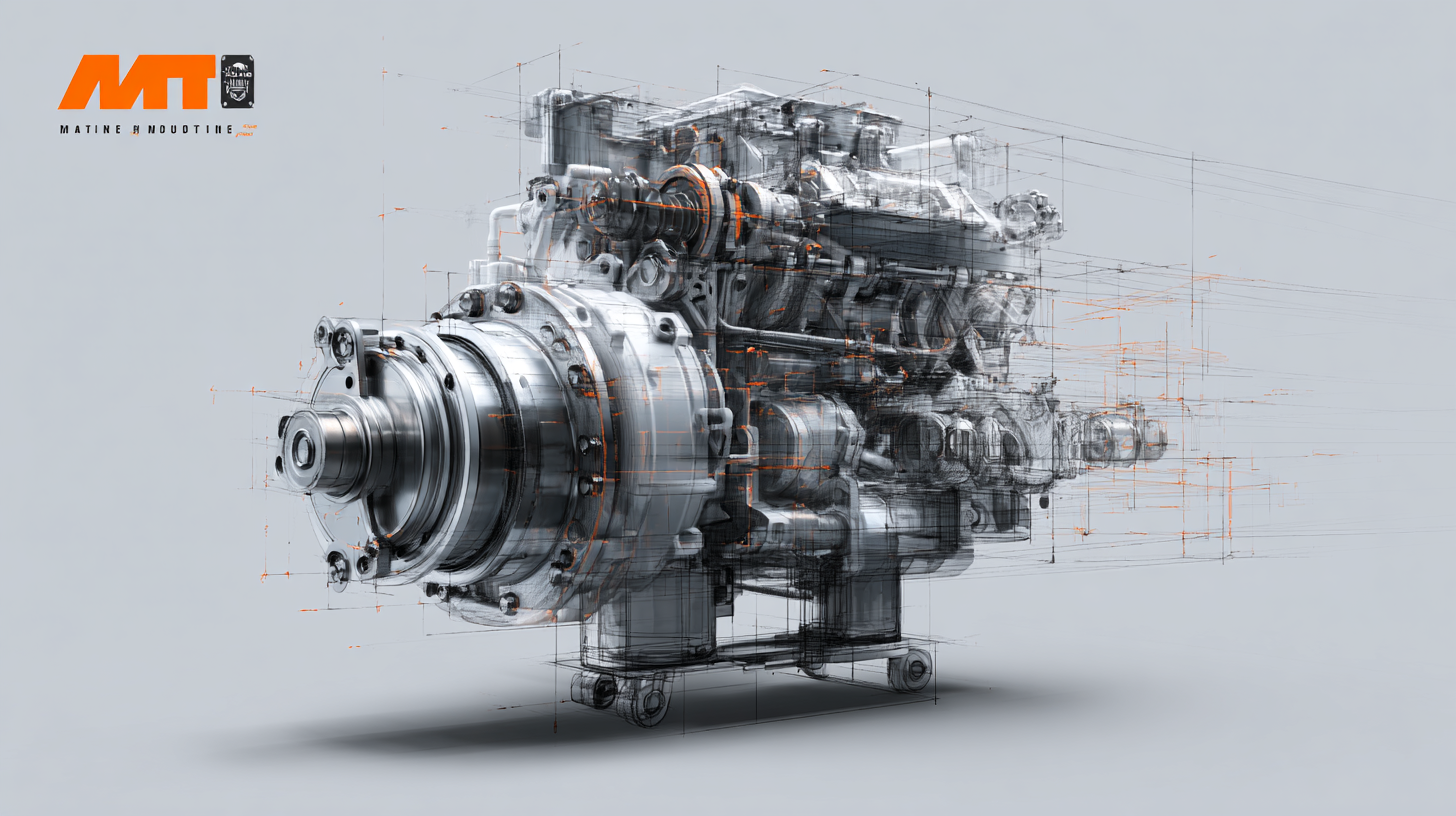

As we look towards 2025, emerging technologies are poised to significantly reshape the landscape of automotive engine mounts. Innovations in materials science, such as the use of advanced composites and lightweight materials, will enhance the performance and durability of engine mounts. These materials not only reduce the overall weight of vehicles, contributing to improved fuel efficiency, but also provide better vibration damping capabilities. This shift toward more efficient materials aligns with the industry's growing emphasis on sustainability and performance.

As we look towards 2025, emerging technologies are poised to significantly reshape the landscape of automotive engine mounts. Innovations in materials science, such as the use of advanced composites and lightweight materials, will enhance the performance and durability of engine mounts. These materials not only reduce the overall weight of vehicles, contributing to improved fuel efficiency, but also provide better vibration damping capabilities. This shift toward more efficient materials aligns with the industry's growing emphasis on sustainability and performance.

Moreover, the integration of smart technology into engine mounts is set to revolutionize their functionality. Sensors embedded within the mounts can monitor vibrations and engine performance in real time, allowing for predictive maintenance and enhanced vehicle diagnostics. This technology will not only improve the driving experience by offering smoother rides but also extend the lifespan of engine components by identifying potential issues before they escalate. As suppliers prepare for procurement in 2025, focusing on these emerging technologies will be crucial for maintaining competitive advantage in a rapidly evolving automotive market.

Key Differences Between Traditional and Advanced Engine Mount Systems

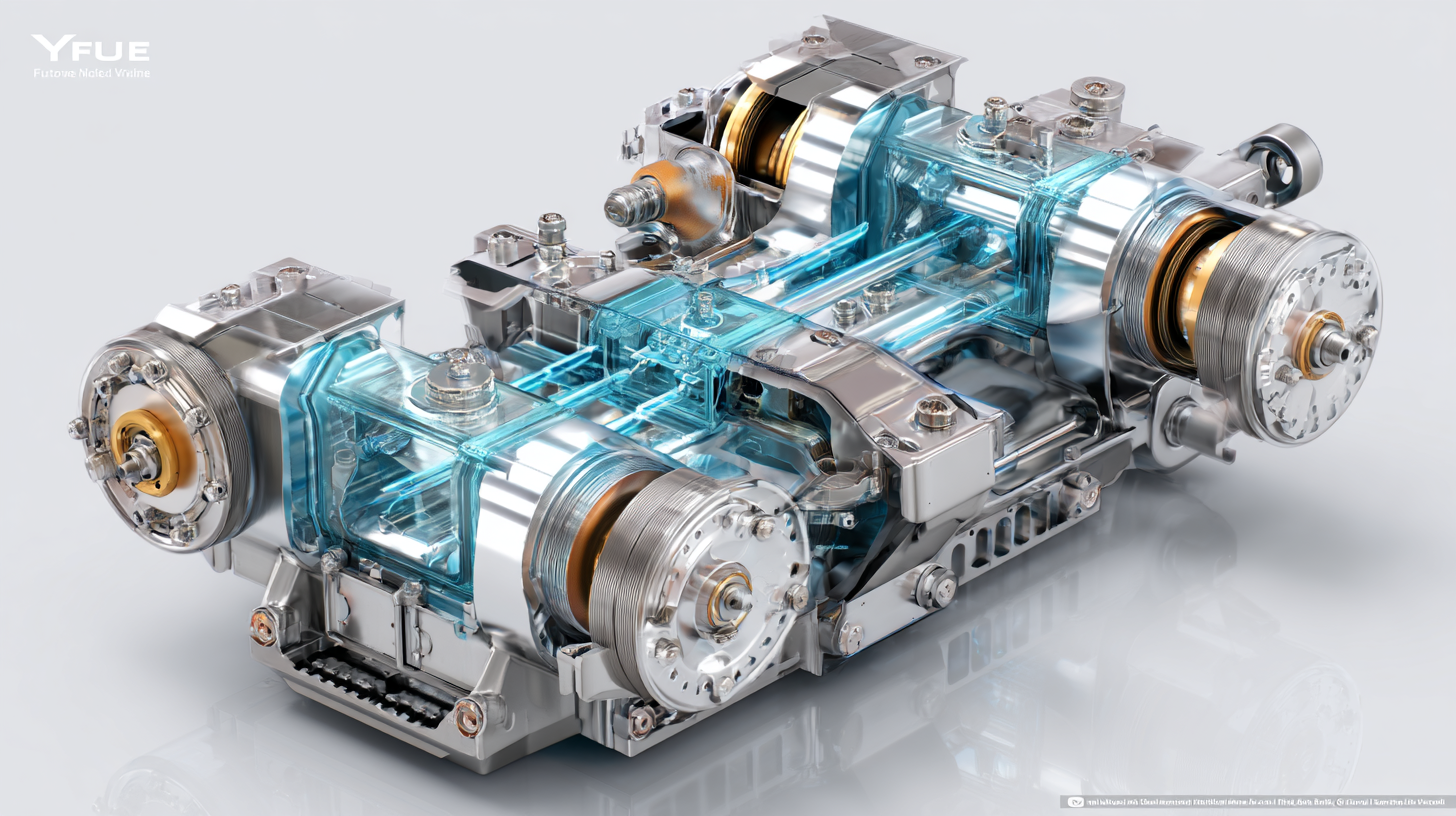

The automotive industry is evolving rapidly, and so are the technologies behind engine mount systems. Traditional engine mounts, often made of rubber and metal, primarily serve to isolate vibrations from the engine and support its weight. They have been the standard for many years due to their relatively low cost and simplicity. However, as vehicle performance and comfort expectations rise, advanced engine mount systems are becoming increasingly relevant. These modern solutions utilize sophisticated materials and technologies, such as liquid-filled mounts or active systems that adapt to changing driving conditions.

The key difference lies in their functionality and performance benefits. Traditional mounts do a decent job of minimizing engine vibrations, but they lack the versatility offered by advanced systems, which can adjust in real-time to enhance ride quality and vehicle dynamics. Advanced mounts can significantly reduce noise, vibration, and harshness (NVH), providing a smoother driving experience. Additionally, they often contribute to overall vehicle weight reduction and improved fuel efficiency, making them a compelling choice for future automotive designs. As we approach 2025, procurement strategies must prioritize these innovations to stay competitive in the evolving market.

Global Market Trends Influencing Engine Mount Procurement Strategies

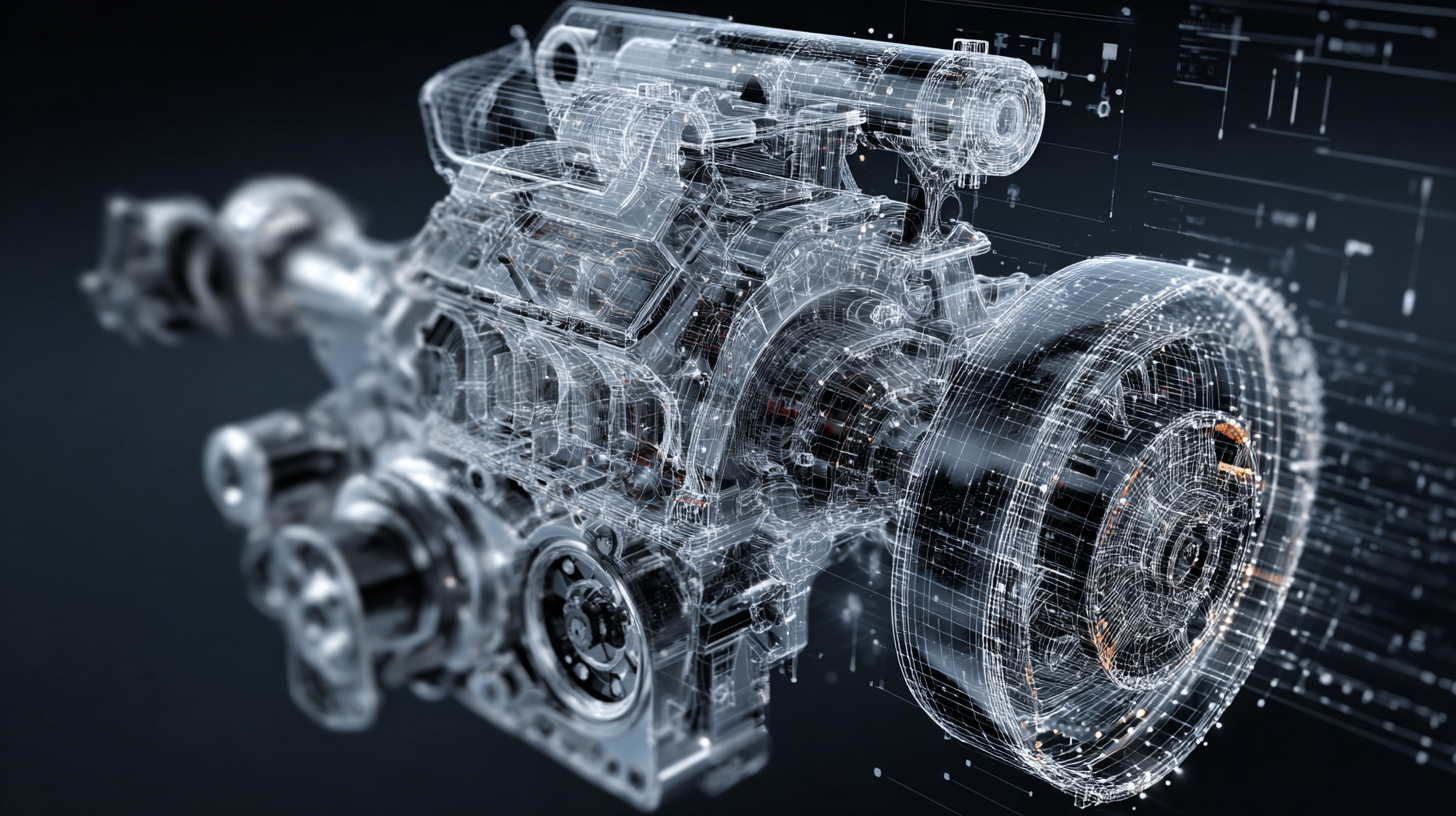

As the automotive industry evolves, the procurement strategies for engine mounts must adapt to significant global market trends shaping the future landscape. In 2025, manufacturers will face an increasing demand for lightweight, durable, and cost-effective materials that not only enhance vehicle performance but also comply with stringent environmental regulations. Manufacturers are exploring innovative composites and advanced polymers, which not only provide superior vibration dampening but also contribute to weight reduction—an essential factor in fuel efficiency and sustainability initiatives.

Furthermore, the shift towards electric vehicles (EVs) is revolutionizing engine mount designs and specifications. With the decrease in traditional engine compartment sizes and the increase in the need for battery management systems, procurement strategies will have to focus on adaptability and compatibility with new technology. This includes sourcing mounts that can accommodate varying battery configurations and new drivetrains, highlighting the necessity for suppliers to stay agile and informed about technological advancements within the industry. Emphasizing collaboration with suppliers who possess expertise in these emerging technologies will be crucial for procurement professionals aiming to stay ahead in the competitive landscape.

Sustainability Considerations for Engine Mount Materials in 2025

As the automotive industry shifts towards sustainability, the materials used for engine mounts are undergoing significant transformations. By 2025, manufacturers are expected to prioritize eco-friendly materials such as bioplastics and recycled composites. According to a recent report from MarketsandMarkets, the global automotive plastics market is projected to grow at a CAGR of 8.5% from 2020 to 2025, driven by the demand for lightweight and sustainable components. This trend emphasizes the need for procurement teams to reassess their sourcing strategies.

Tip: When selecting materials for engine mounts, consider those that not only meet performance standards but also contribute to a lower carbon footprint. Working with suppliers who prioritize sustainable practices can enhance your brand's reputation while aligning with regulatory requirements.

Additionally, innovations in material science are leading to the development of advanced polyurethane foams that offer superior durability and noise-dampening properties. These materials can significantly reduce the vehicle's overall weight, improving fuel efficiency. According to a study by the Society of Automotive Engineers (SAE), reducing weight by just 10% can result in a 6-8% increase in fuel economy.

Tip: Regularly evaluate your supplier's sustainability credentials and their commitment to reducing environmental impact. Engaging with stakeholders about material choices can also lead to collaborative innovations that benefit the entire supply chain.

Future of Automotive Engine Mounts in 2025

Essential Supplier Criteria for Engine Mounts in the Automotive Industry

When procuring engine mounts for the automotive industry, establishing essential supplier criteria is crucial for ensuring quality and performance. Suppliers should demonstrate a strong track record in the industry, showcasing experience and expertise in manufacturing engine mounts that meet stringent automotive standards. Certifications such as ISO/TS 16949 can indicate a supplier's commitment to quality management systems tailored for automotive applications. Furthermore, assessing a supplier's ability to innovate—particularly in materials and manufacturing processes—can significantly affect the longevity and effectiveness of engine mounts in modern vehicles.

Another vital criterion is the supplier's capability for scalability and responsiveness to market demands. As the automotive landscape evolves, so do the requirements for engine mounts, such as weight reduction and enhanced vibration damping. Suppliers should have the flexibility to adapt to changing technologies and regulatory requirements while maintaining competitive pricing. Additionally, fostering strong communication channels can ensure that procurement teams remain aligned with suppliers on timelines, production schedules, and quality assessments, which is imperative for successful project execution.

In sum, focusing on these essential criteria can lead to securing reliable partnerships that drive innovation and efficiency in automotive engine mounting solutions.