- English

- русский

- العربية

- tiếng Việt

- Türkçe

- Deutsch

- 日本語

- 한국어

- ภาษาไทย

- Indonesia

- שפה עברית

- Português

- Español

- Français

- Italiano

- Nederlands

- Polski

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Gaeilge

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Unmatched Quality and Reliability of Best Automotive Engine Mounts from Leading Chinese Manufacturers

In recent years, the automotive industry has witnessed a transformative shift towards enhanced quality and reliability, particularly in components such as the Automotive Engine Mount. According to a report by Allied Market Research, the global automotive engine mounts market is projected to reach USD 5.2 billion by 2027, growing at a CAGR of 7.3% from 2020. This growth is driven by increasing demand for vehicles with improved performance and reduced noise, vibration, and harshness (NVH) levels. Leading Chinese manufacturers have established themselves as key players in this sector, leveraging cutting-edge technology and stringent quality control measures to produce engine mounts that meet international standards.

As we delve into the unmatched quality and reliability of the best automotive engine mounts offered by these manufacturers, we will explore the implications for the automotive market, particularly as we approach the technological trends earmarked for 2025.

Unveiling the Superior Quality Standards of China’s Automotive Engine Mounts

China has rapidly emerged as a leading player in the automotive components market, particularly in the manufacturing of engine mounts. Recent industry reports indicate that the Chinese automotive parts market is projected to reach $300 billion by 2025, with engine mounts accounting for a significant portion of this growth. The unparalleled scalability and technological advancements of Chinese manufacturers allow for products that not only meet but exceed international quality standards.

The superior quality of automotive engine mounts from Chinese manufacturers is backed by rigorous testing and compliance with global certifications, such as ISO 9001 and TS 16949. These engine mounts are subjected to extensive durability and environmental testing, ensuring reliability under various driving conditions. According to a study by MarketsandMarkets, the demand for high-performance engine mounts is expected to grow by 6.5% annually through 2024, largely due to the reliability and enhanced noise, vibration, and harshness (NVH) characteristics provided by these products. This positions Chinese manufacturers at the forefront of delivering unmatched quality in engine mounts to an evolving global automotive market.

Unmatched Quality and Reliability of Best Automotive Engine Mounts from Leading Chinese Manufacturers

| Engine Mount Type | Material | Load Capacity (kg) | Vibration Damping (%) | Temperature Range (°C) |

|---|---|---|---|---|

| Hydraulic Mount | Rubber and Fluid | 180 | 90 | -30 to 100 |

| Solid Mount | Aluminum Alloy | 210 | 70 | -40 to 120 |

| Polyurethane Mount | Polyurethane | 200 | 85 | -20 to 90 |

| Rubber Mount | Natural Rubber | 150 | 80 | -30 to 80 |

| Active Mount | Active Control System | 190 | 95 | -20 to 110 |

Key Performance Metrics: Comparing Chinese Engine Mounts with Global Competitors

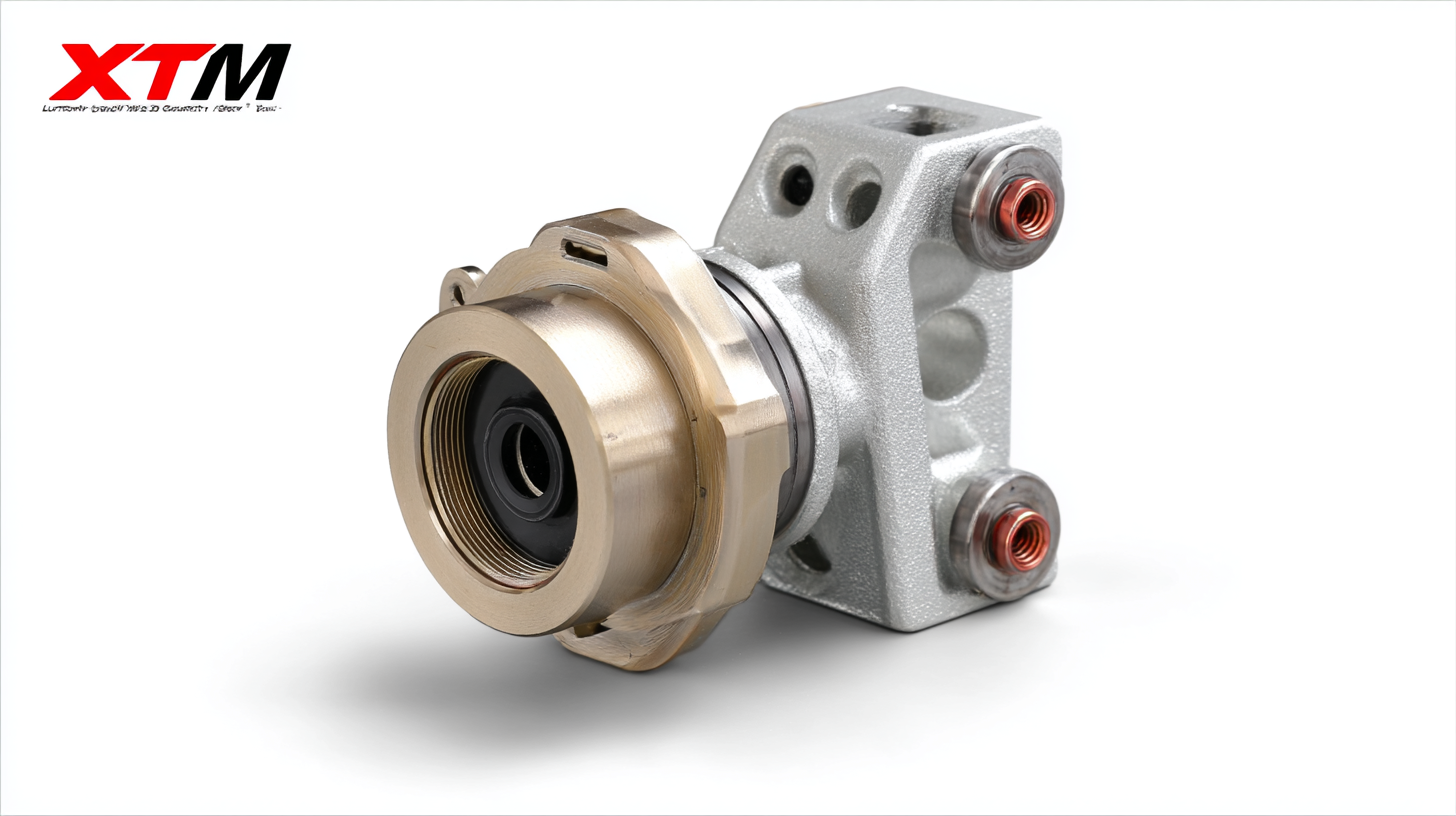

When evaluating the performance of automotive engine mounts, it is essential to consider various key metrics that influence quality and reliability. Leading Chinese manufacturers are increasingly recognized for producing engine mounts that not only meet but often exceed global standards. Key performance indicators such as material durability, vibration dampening capabilities, and load-bearing capacity play a crucial role in assessing the effectiveness of these components in maintaining engine stability and improving overall vehicle performance.

When evaluating the performance of automotive engine mounts, it is essential to consider various key metrics that influence quality and reliability. Leading Chinese manufacturers are increasingly recognized for producing engine mounts that not only meet but often exceed global standards. Key performance indicators such as material durability, vibration dampening capabilities, and load-bearing capacity play a crucial role in assessing the effectiveness of these components in maintaining engine stability and improving overall vehicle performance.

Chinese engine mounts have shown impressive results in comparisons with global competitors. For instance, while many international brands focus on traditional materials that may not withstand extreme conditions, innovative Chinese manufacturers are utilizing advanced composites and high-grade rubber that endure harsher environments. Additionally, these mounts demonstrate superior vibration isolation, which contributes to more comfortable ride quality and reduced noise levels inside the cabin. This combination of performance and cost-effectiveness positions Chinese engine mounts as formidable competitors in the global automotive market.

The Technological Advancements Behind China's Leading Engine Mount Manufacturers

The realm of automotive engineering has been significantly transformed by the rapid technological advancements made by leading Chinese manufacturers in engine mount production. These companies are at the forefront, incorporating cutting-edge materials and innovative design techniques to enhance durability and performance. This evolution not only optimizes engine functionality but also contributes to the overall comfort and safety of the vehicle. By adopting advanced manufacturing processes such as precision molding and automated quality control, Chinese engine mount producers ensure the unmatched quality that enhances vehicle longevity.

Tip: When selecting engine mounts, consider the material's flexibility and durability, as these factors are crucial for minimizing vibrations and noise. Look for mounts made from high-quality rubber or polymer compounds that can withstand extreme temperatures and offer greater resilience.

Moreover, the integration of smart technology in engine mount systems is revolutionizing how vehicles respond to different driving conditions. Smart mounts equipped with sensors can adjust stiffness in real-time, providing a smoother riding experience and improved handling. This advancement exemplifies the commitment of Chinese manufacturers to push the boundaries of automotive technology.

Tip: Always check for certifications and reviews when purchasing engine mounts, ensuring they meet industry standards for quality and performance. This will help you invest in reliable products that enhance your vehicle's operation.

Unmatched Quality and Reliability of Best Automotive Engine Mounts

Analyzing the Market Demand for Engine Mounts and the Role of Chinese Suppliers

The demand for automotive engine mounts has seen a significant rise in recent years, driven by the growth of the automotive industry and the increasing emphasis on vehicle performance and safety. As such, Chinese manufacturers have stepped up to meet this demand, leveraging their production capabilities to supply high-quality and reliable engine mounts to both domestic and international markets. This surge in demand highlights the strategic role that Chinese suppliers play in the global automotive supply chain.

Moreover, the collaboration between Chinese manufacturers and foreign automobile companies is expected to strengthen further as they seek to improve craftsmanship and innovate product designs. The automotive industry is transitioning towards electric and hybrid vehicles, which necessitates advanced engine mounting solutions to accommodate new technologies. By embracing these changes, Chinese manufacturers are not only meeting current market needs but also positioning themselves as vital players in the future of automotive engineering. This evolution in the market presents a unique opportunity for businesses to establish strong partnerships with leading Chinese suppliers.

Sustainability Practices in the Production of Automotive Engine Mounts in China

In recent years, leading Chinese manufacturers of automotive engine mounts have increasingly prioritized sustainability practices in their production processes. These manufacturers are adopting eco-friendly materials and technologies that not only reduce waste but also enhance the overall lifecycle of their products. By implementing advanced manufacturing techniques, they are able to minimize energy consumption and lower their carbon footprint, which is crucial in today's environmentally-conscious market.

Moreover, many of these companies are focusing on recycling and reusing materials in their operations. This commitment not only helps in conserving natural resources but also supports the global shift towards a circular economy. By utilizing recycled materials in the production of engine mounts, these manufacturers are setting an industry standard for sustainability that resonates with both consumers and regulatory bodies alike. The shift toward more sustainable practices is not just a trend, but a vital component of the operational ethos for leading automotive suppliers in China, ensuring that quality and reliability go hand-in-hand with environmental responsibility.